GRUNDFOS Druckerhöhungsanlage Hydro MPC-S 3 CR 32-4 Art. 96575873

Teilen via

- Auf Lager

Technische Daten

Hydro MPC-S 3 CR 32-4

Membranbehälter, Komponenten zur Wassermangel- überwachung und alternative Bedieneinheiten können aus der Zubehörliste ausgewählt werden. Nettogewicht: 519 kg

Pressure booster system supplied as compact assembly according to DIN standard 1988/T5.

The pumps are all mains-operated CR(I) pumps.

|

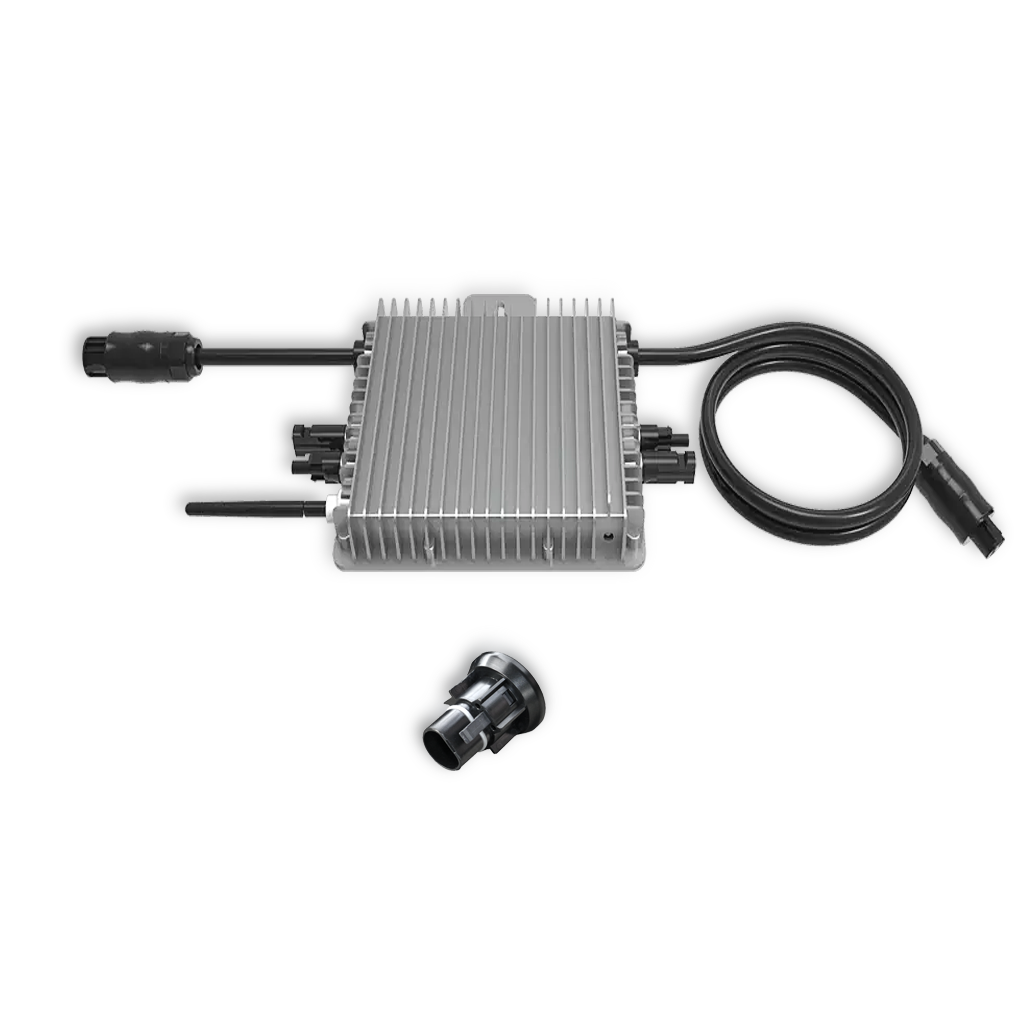

The system consists of these parts:

|

Dry-running protection and diaphragm tank are available according to the list of accessories.

Pump operation is controlled by Control MPC with the following functions:

|

Pumps, piping, cabling complete as well as Control MPC are mounted on the base frame. The booster system has been preset and tested.

| Fördermedium: | Wasser | |

| zul. Mediumtemp.: | 5 °C .. 60 °C | |

| Max. Betriebsdruck: | 16 bar | |

| Max. Förderstrom d. Anlage: | 120 m³/h | |

| Nennstrom der Anlage: | 42.7 A | |

| Motorbemessungsleistung: | 7.5 kW |